Certified Company

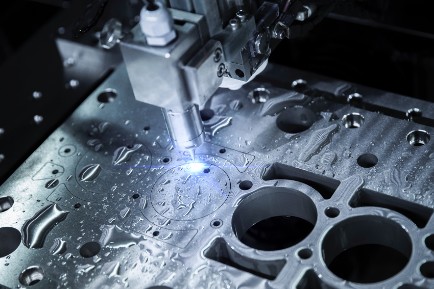

Overview: Our Sheet Metal Fabrication Process?

Sheet Metal Fabrication

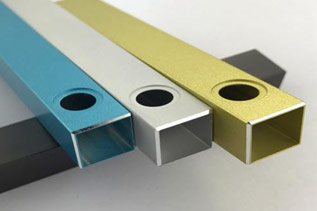

CNP offers a variety of metals and alloys, including stainless steel, copper, and aluminum.

The Basics Of Sheet Metal Fabrication

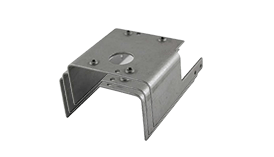

Unlike traditional sheet metal shops, we have infinite capacity and an easy-to-use online quoting system ensuring on-time shipment every time—whether you need a single part or 500 parts. Sheet metal fabrication is the process of forming a piece of metal into a desired shape through bending, stretching, and removal of material. At Rapid, we use press brake punches and die tooling to bend and stretch flat stock into its final geometry. The sheet metal prototyping process is most often used when form, fit, and function are all a priority. Typical sheet metal parts we manufacture include enclosures, brackets, assemblies, weldments, cabinets, and other components.

Sheet Metal Cutting Types

Features of Sheet Metal Fabrication

Advantages

Drawbacks

Available sheet metal fabrication processes

| Name | Description | Allowable sheet thickness |

|---|---|---|

| Laser cutting | This manufacturing process uses a high-power laser beam to cut a material sheet. | 0.5-10mm |

| Bending | This manufacturing process uses a dies to produce a U-shape | 0.5-6mm |

Tolerances for sheet metal fabrication

| Feature | Tolerance |

|---|---|

| Cutting feature | ±.0078"(0.2mm) |

| Bend angle | ±1.0° |

| Bend to edge | +/-0.010"(0.254mm) |

Available Materials for sheet metal fabrication

| Aluminum | Copper | Steel |

|---|---|---|

| Aluminum 5052 | Copper 101 | Stainless Steel 301 |

| Aluminum 6061 | Copper 260 (Brass) | Stainless Steel 304 |

| Copper C110 | Stainless Steel 316/316L | |

| Steel, Low Carbon |

Our standard surface finishes

| Requirement | Specification |

|---|---|

| Grit | #120 |

| Color | Uniform matte of raw material color |

| Part masking | Indicate masking requirements in technical drawing |

| Requirement | Specification |

|---|---|

| Grit | #120 |

| Color | Uniform matte of raw material color |

| Part masking | Indicate masking requirements in technical drawing |

| Requirement | Specification |

|---|---|

| Thickness | 8 - 12 μm (clear), 4 - 8 μm (color) |

| Color | Black, clear or any RAL code or Pantone number |

| Part masking | Indicate masking requirements in technical drawing |

| Requirement | Specification |

|---|---|

| Thickness | 18 - 72μm |

| Color | Black or any RAL code or Pantone number. |

| Part masking | Indicate masking requirements in technical drawing. |