Certified Company

Overview

Vacuum Casting

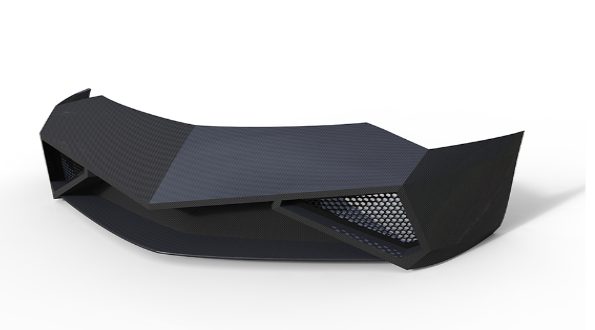

CNP’s rapid vacuum casting does very well for the manufacturing of low-cost plastic parts. The tooling for this manufacturing is not very durable, but it is good for low volume production.

Vacuum casting (also known as polyurethane casting) is an economical alternative to small batch injection molding of plastic parts.

It can be used to simulate the final molded part or finished product. Generally speaking, the mold is made of silicone rubber and uses CNC or SLA part as a main mode.

These molds replicate details and textures and give a consistent finish from one part to the next.

It can be used to simulate the final molded part or finished product. Generally speaking, the mold is made of silicone rubber and uses CNC or SLA part as a main mode.

These molds replicate details and textures and give a consistent finish from one part to the next.

Vacuum casting is a specialized technique for making high-fidelity copies of master patterns using inexpensive silicone molds and pourable casting resins.

Copies made in this way demonstrate the same quality as plastic injection molded parts while taking only a fraction of the time and expense to produce.

Copies made in this way demonstrate the same quality as plastic injection molded parts while taking only a fraction of the time and expense to produce.

Features

| 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|

| Low cost of silicone mold | Fast tooling, normal 1 to 2 days to complete the mould | Easy to release parts from the mould due to the non-stick property of the silicone rubber | High precision and fine details | Excellent surface finish |

Materials

| ABS | PMMA | PC | Reliability |

|---|---|---|---|

| (ABS is the acronym of Acrylonitrile Butadiene Styrene, which refers to acrylonitrile-butadiene-styrene copolymer) is a kind of thermoplastic polymer structure material with high strength, good toughness and easy processing and molding, also known as ABS resin . | PMMA is the abbreviation code for polymethyl methacrylate material. Commonly known as plexiglass, it is the most excellent and reasonably priced variety among synthetic transparent materials so far. | Polycarbonate is a high molecular weight polymer containing carbonate groups in the molecular chain. | Polypropylene is a semi-crystalline thermoplastic. It has high impact resistance, strong mechanical properties, resistance to a variety of organic solvents and acid and alkali corrosion. |