Certified Company

We are the world class prototyping manufacturing providing the highest quality products, services, and solutions to our customers.

HIGHLY-SKILLED ENGINEERING TALENT

Our team includes more than 58 highly skilled engineers, experienced craftsmen, and machining specialists, many of whom have decades of experience in manufacturing and prototyping production. The quality of our products depends upon the knowledge and experience of the team.

We have State-of-the-art facilities

CNP’s state-of-the-art production facilities are located in Xi'an, China. Our four buildings occupy 6,000 square feet and house more than 240 top-end machine tools. Our large number of machine tools allows us to choose the precise machine suited for the specific machining task.

Time-tested proprietary development processes

Rapid production cycles are critical to our clients’ success. CNP’s start-to-finish prototype process allows us to achieve some of the shortest turnaround times in the industry. A typical project can be completed in 24 hours after receipt of 2D/3D data.

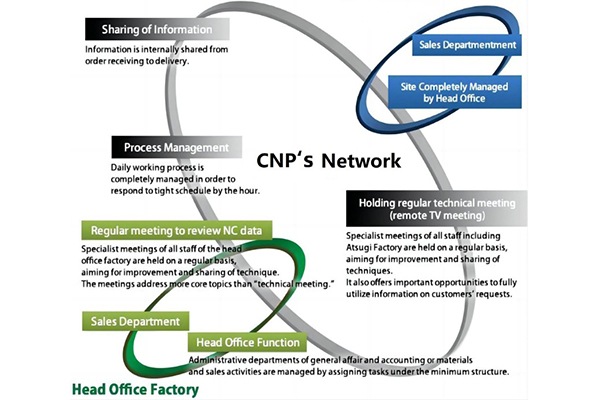

Our unique network

We are building a network that strongly connects the field, sales, and customers with each other so that salespeople always respond quickly. By doing this it is possible to do all the work without returning to the office. Our engineering team is connected directly to the factory floor through an optical fiber network. This allows us to achieve exceptional efficiency by feeding our 3D CAM developed designs and NC data directly to our machine tools. And the lead time usually will be 3-5days.

Machining equipments

To achieve high-precision processing, we have several specialized finishing machines made in Germany and Japan. Such as a centerless grinder capable of machining with a roundness of 0.1μm, as well as a variety of flat surface grinders, cylindrical grinders, and other polishing machines to meet the demands of ultra-precision machining on the submicron precision products that are used in the engines.

Inspection system

CNP features a full range of precision measuring and inspection equipment to make sure that each part conforms to the tightest specifications. Regarding each request of our customers, in our internal network environment, information obtained in meetings with our customers and other data including drawings, CAD data, NC data, etc. necessary for inspection are stored in the database and shared.

CNP consistently meets constrained schedules to deliver top quality models each time. Their customer service is second to none in the passion and commitment to ensure the customer’s requirements are met. Their overall level of excellence remains the reason that they are our primary source for rapid prototyping.

Electronics Company

Engineer

CNP is my go to prototyping supplier when I want a high quality prototype delivered on time. I know I will get a prototype that has the look of a release ready product and I will get it on the promised delivery date. I frequently get compliments on CNP built parts for their fit and finish.

Medical Device Company

Engineer

Excellent machining quality and accuracy within specification. Attention to fine detail and edge chamfering very impressive. Logo etching very good. Surface finish - light machining perfect.

Manufacturing Company

Engineer