Certified Company

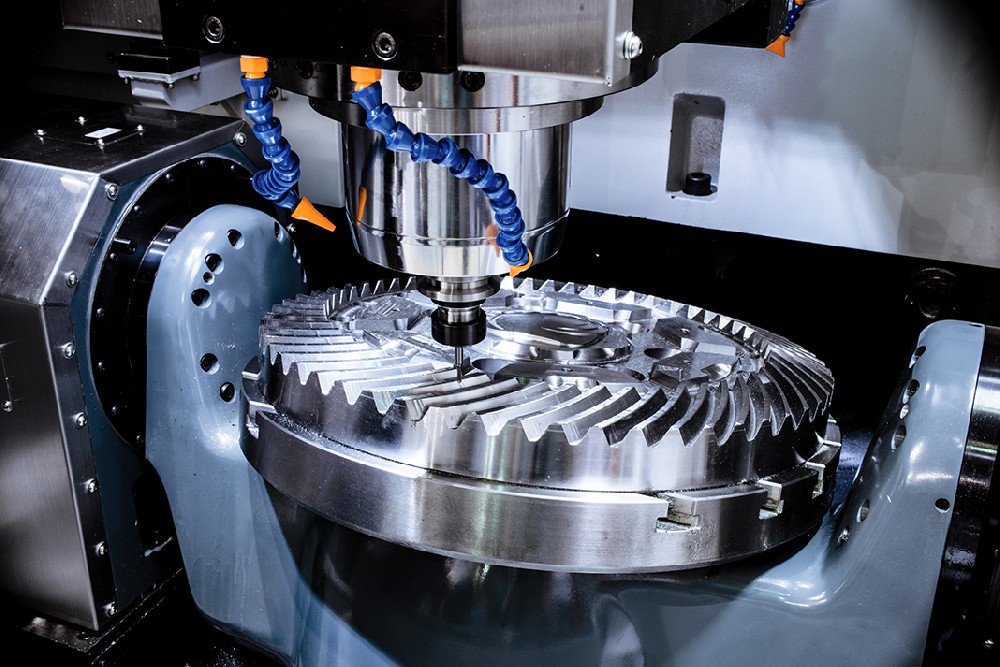

Latest Trends in CNC Rapid Prototype

Rapid manufacturing with CNC machining delivers precise, high-quality parts quickly and cost-effectively. With the right service provider, you can create any CNC rapid prototype from a wide range of metals and plastics. Reputable companies can customize the process to meet any requirement while controlling tolerances to DIN-2768-1 Medium for plastics and Fine for metals.

CNC machining is among the oldest manufacturing technologies, but it evolved with new advancements, applications, and prototyping trends. Here are some of the latest trends shaping the industry and making the process more cost-effective and efficient.

Robotics and automation

Robotics has long been involved in CNC machining, but more manufacturers are recently adopting collaborative robots. Unlike regular industrial robots, they can work closely with human workers while using their intuition to perform more efficiently. They can even learn specific manual actions for custom CNC rapid prototype projects.

Using more axes to cut costs

Conventional CNC machines use linear motion with three axes. Many modern machines have a moving bed with a three-axis milling center. Now, you may consider four- or five-axis machines for detailed cutting that includes a rotational axis.

The fourth axis can help make medical devices and components with complex geometries, and the fifth can perform micromachining, making it possible to create detailed cuts quickly.

It is also possible to retrofit legacy CNC machines to have more axes, such as by adding a trunnion to enable greater rotation and tilt. This way, a three-axis machine can increase its capability to create any CNC rapid prototype with fewer setups.

Better CAD software

Today’s CAD/CAM software solutions are more affordable, intuitive, powerful, user-friendly, and accessible, enabling increased accuracy, efficiency, and innovative workflows. It’s possible to integrate some with machine platforms, 3D viewing systems, and model-based definition software.

These are just some of the latest trends and developments that make CNC machining more reliable and accessible now and for many years to come. They allow manufacturers to complete your CNC rapid prototype quickly and less expensively, so you can reduce your time to market.

Leave a Reply