Certified Company

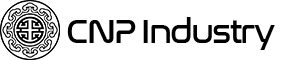

How Do Machinists Handle Sharp Corners in CNC Processing?

Author: Xing Lee Technical Consultation: info.us@cnprototype.com

Challenges of Sharp Corners in Custom CNC Parts

Sharp internal corners present significant challenges in CNC machining. The cylindrical geometry of end mills and drills inherently creates radiused corners in cavities. While specialized methods exist, their substantial costs dictate that sharp corners should only be specified for critical functional requirements.

I. Root Causes of Sharp Corner Challenges

1. Tool Geometry Constraints

The minimum achievable internal radius equals the tool radius. Perfect right angles require infinitesimally small tools - a physical impossibility.

2. Secondary Processing Defects

Forced sharp corner machining through workpiece rotation causes:

- Chatter marks from tool vibration

- 30-50% reduced efficiency

- Surface quality degradation (2-3×Ra increase)

II. Machining Solutions

Solution 1: Optimized Fillet Radius

- Technical Principle

Set radius ≥1/3 cavity depth, matching tool diameter (2-3× depth)

- Process Benefits

40% extended tool life, 25% efficiency gain

- Key Consideration

> "For 18mm cavity with Φ6mm tool: minimum 6mm radius prevents chatter" - ISO 13715 recommendation

Solution 2: T-Bone & Dogbone Features

Type | Characteristics | Application | Material Loss |

| T-Bone | Unidirectional extensio | Sliding fits | 5-8% |

Dogbone | Bidirectional √(R²/2) offset | Precision locating | 12-15% |

Solution 3: EDM Process

Workflow:Electrode prep → Dielectric selection → Parameter setup → Layer erosion → Post-processing

Performance Comparison

| Type | Accuracy(μm) | Surface(Ra) | Speed(mm³/min) |

| Wire EDM | ±5 | 0.8-1.6 | 80-120 |

| Sinker EDM | ±10 | 1.6-3.2 | 150-300 |

III. Decision Tree for Solution Selection

graph TD

A[Sharp Corner Required?] -->|No| B[Standard Fillet]

A -->|Yes| C{Assembly Function}

C -->|Dynamic| D[Dogbone]

C -->|Static| E[T-Bone]

C -->|Non-contact| F[EDM]

F --> G{Conductive?}

G -->|Yes| H[Select EDM Type]

G -->|No| I[Redesign]

We welcome global manufacturing professionals to discuss:

Optimization of complex corner machining

EDM parameter co-debugging

Custom tooling solutions

Contact Engineer

Xing Lee Technical Director

Leave a Reply